The Carbon Support Rod from Zhejiang Dehong Carbon Fiber Composite Material Co., Ltd. is a revolutionary material that is transforming industries that demand strength, heat resistance, and durability in extreme environments. Made from advanced carbon-carbon composite technology, the Carbon Support Rod provides exceptional mechanical properties that outperform traditional materials such as metals and plastics. Designed for high-performance applications across aerospace, automotive, energy, and industrial sectors, this versatile product offers an unbeatable combination of lightweight construction, high strength, and exceptional thermal stability.

What is the Carbon Support Rod?

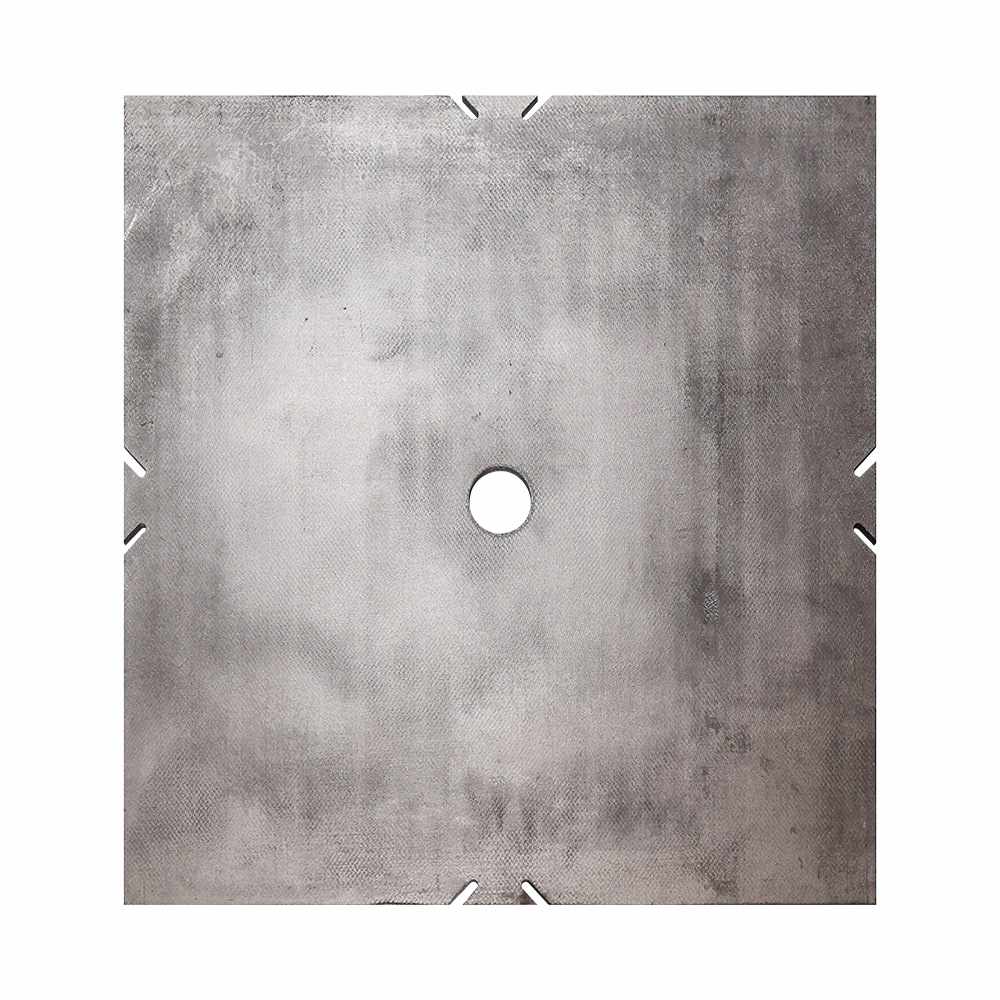

The Carbon Support Rod is crafted from carbon-carbon composites, which combine carbon fibers with a resin matrix. After being subjected to a specialized high-temperature treatment process, this material exhibits remarkable properties, including high mechanical strength, low weight, and excellent heat resistance. The Carbon Support Rod is ideal for industries that require materials that can withstand extreme temperatures, high mechanical loads, and wear over prolonged periods. It is engineered to perform reliably in some of the most challenging and demanding conditions, making it the material of choice for industries where performance and safety are paramount.

Key Features of the Carbon Support Rod

Outstanding Heat Resistance

One of the most remarkable features of the Carbon Support Rod is its ability to withstand high temperatures. Withstanding temperatures of up to 3,000°C, the Carbon Support Rod is perfect for applications in environments where heat resistance is critical. Whether used in aerospace applications like rocket nozzles, turbine engines, or industrial furnaces, the Carbon Support Rod maintains its mechanical strength and structural integrity at elevated temperatures where traditional materials would degrade. This makes it a go-to choice for high-performance industries that require components to perform under extreme heat conditions.

Lightweight with High Strength-to-Weight Ratio

In addition to its heat resistance, the Carbon Support Rod offers an excellent strength-to-weight ratio. Its lightweight nature makes it especially useful in aerospace and automotive applications, where reducing weight without sacrificing strength is crucial for improved performance and fuel efficiency. The Carbon Support Rod provides the necessary mechanical support for components that endure high stress and loads while keeping weight to a minimum. This ensures that applications such as turbine blades, engine components, and high-performance vehicle parts benefit from both reduced mass and enhanced structural support.

Durability and Longevity

The Carbon Support Rod is designed for exceptional durability. It is resistant to wear, corrosion, and thermal cycling, making it ideal for high-demand applications in industries such as energy and aerospace. The material can withstand repeated exposure to thermal and mechanical stresses without compromising its performance, ensuring a long service life. In energy production, whether in nuclear reactors or solar thermal plants, the Carbon Support Rod remains stable over extended periods, reducing the need for frequent replacements and minimizing downtime in critical systems.

Versatile Applications Across Industries

The Carbon Support Rod is versatile, serving a wide range of industries and applications, including:

Aerospace: The Carbon Support Rod is a critical component in turbine blades, heat shields, and rocket nozzles, where it offers the necessary heat resistance and mechanical strength to perform reliably at high altitudes and in high-pressure environments.

Automotive: In high-performance and electric vehicles, the Carbon Support Rod contributes to weight reduction while enhancing strength, heat resistance, and performance. Its use in automotive parts helps optimize fuel efficiency and improve overall handling.

Energy: The Carbon Support Rod is used in power generation systems, such as nuclear reactors, thermal power plants, and energy storage systems, where it is subjected to extreme conditions. Its ability to handle high temperatures and mechanical stress makes it an indispensable part of modern energy solutions.

Industrial Manufacturing: In sectors like metal forging, semiconductor production, and ceramics, the Carbon Support Rod provides the mechanical strength and thermal stability necessary for high-temperature processes.

Customization for Specific Needs

Zhejiang Dehong offers tailored solutions with the Carbon Support Rod to meet the specific needs of clients. Whether altering the size, enhancing thermal properties, or improving the material's strength, the company can customize the Carbon Support Rod to suit different applications and environments. This ensures that each Carbon Support Rod delivers maximum performance, efficiency, and durability based on the unique requirements of the project.

Why Choose Zhejiang Dehong’s Carbon Support Rod?

Zhejiang Dehong Carbon Fiber Composite Material Co., Ltd. is known for its innovation, quality, and expertise in the field of carbon fiber composites. With years of experience in developing high-performance materials, the company ensures that every Carbon Support Rod meets the highest industry standards. The company’s commitment to customer satisfaction and product excellence makes it a trusted partner for industries seeking reliable, cutting-edge solutions.

Conclusion

The Carbon Support Rod from Zhejiang Dehong Carbon Fiber Composite Material Co., Ltd. is a high-performance, durable, and versatile material that offers a range of benefits for industries requiring extreme heat resistance, mechanical strength, and long-term reliability. Whether used in aerospace, automotive, energy production, or industrial manufacturing, the Carbon Support Rod delivers consistent and efficient performance in the most demanding applications. Its lightweight nature, high strength, and exceptional heat resistance make it the ideal choice for high-performance projects that require both durability and efficiency.

Write a comment ...